Rear Crankshaft Rope Seal Replacement Without Removing Crank

on the 1982 300CD (OM617)

by ROLLGUY

05/14/11

Rear Crankshaft Rope Seal Replacement Without Removing Crank

I pulled the engine (617) out of my CD to fix some oil leaks. I wanted to replace the front and rear crankshaft seals. The front was fairly easy, but I "opened up a bag of worms" on the rear. I made the mistake of trying to push the rear crankshaft seal around the journal like I used to do on Chevy V8's. Like the numbskull that I can be, I did not consult this forum first and I ruined the old rope seal. I was committed now, and had to replace the upper seal. I went on the forum (a little late) and searched for a how-to on rear seal replacement. Somewhere I read that someone thought it was possible to remove the main caps and lift the crank to get enough room to remove the old seal and replace it. That is they THOUGHT it was possible. Since I did not want to remove the head in order to remove the crank, I decided to at least try it. Well, GOOD NEWS! It is possible, and it is done!

I decided I would take photos and do a how-to for those that would like to replace their rear seal without removing the crank.

Here is the process:

Remove the upper oil pan so you can suspend the engine with chain through the engine damper holes so the flywheel and adapter plate can be removed.

With your engine on an engine stand (bolted to the adapter plate holes), remove the valve cover, cam chain guide, and cam gear.

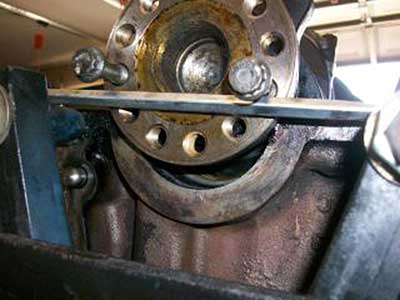

Next, remove the oil pump and main caps.

You will need to remove the oil jet for the cyl that is on the bottom of it's stroke (to allow the piston to go further down the cyl).

Raise the crank up evenly (about 3/4") and support it in any way that will hold it. I used a piece of wood in front, and a screwdriver in the rear. Remove the old seal. Clean out the seal groove with brake cleaner.

Now would be a good time to replace the front seal as well, providing the pulleys and harmonic balancer are removed before removing main rod caps.

The old and new seal.

Install the new seal so about 1/4 inch is sticking out above the deck on one side. Use a 1/4 drive socket extension to force the seal in the groove, rolling it on the seal surface. There is a pin in the very center, so more pressure will be required there. Put assembly lube on all main journals, and the seal. Lower crank back into the upper bearings.

Install the main caps and torque to proper specs (66 ft. lbs.). Install the oil pump. Trim the seal leaving it 1 mm proud of the deck on both sides. Be careful not to score the surface of the crank. Install the other half of the seal in the upper pan and install the pan using the proper metal to metal sealant (described in another thread).

I will let you know how it worked when I get the engine in the car.

Discuss this DIY here.

-ROLLGUY

CategoryDiy