Oil Temperature Gauge Install

on the 1987 300D Turbo (W124, OM603)

by Jeremy5848

07/04/11

300D Oil Temperature Gauge DIY (W124, OM603)

In part because of the discussion in this thread, I decided to install an oil temperature gauge in my 1987 300D Turbo (W124, OM603). The other reason was that as an engineer, I like to measure things, whether I really need to or not. The surprising result was not so much the temperatures (engine oil 200ºF or 93ºC, transmission fluid a little less) but the time it took to get the engine and transmission warmed up.

This DIY is applicable to most engines, Mercedes or not. There will be differences in the way the senders mount and gauge placement is pretty much a matter of personal taste. YMMV. Caution: This DIY involves working under the car. Safety first! Never work under a car supported only by a jack. Always put the car in gear (or in Park), set the parking brake, and chock the wheels that are on the ground.

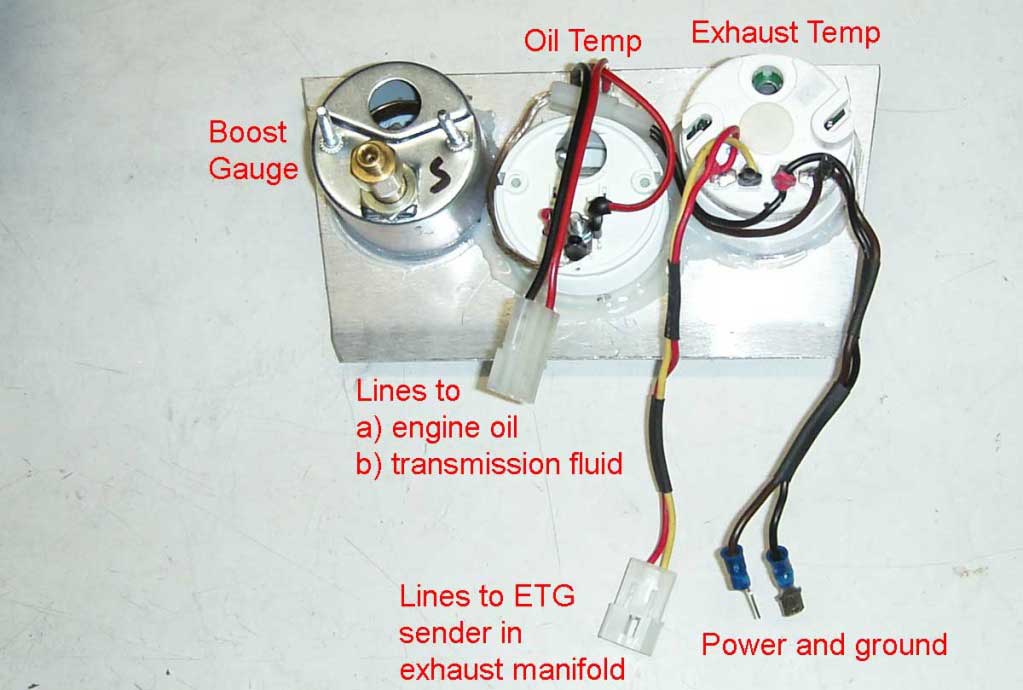

I purchased a VDO oil temperature gauge (model 310-106, range 120-300ºF). I would have preferred a Celsius model and they are probably available but I didn't search very hard. Since this is an electric gauge, I was able to add a switch and monitor not only the engine oil temperature but also the transmission fluid temperature.

Since I already had replaced the ashtray in my 300D with a 3-gauge panel and the panel was full, I had to make room. I decided that the voltmeter was not something I needed to look at all the time so I moved it to the glove box. The voltmeter is mounted in a little metal bracket (VDO 701-2142) and is wired to the light for the glove box. When the glove box door is opened, the voltmeter and its internal illumination come on with the glove box light.

Placement of temperature senders is controversial. Should you put the sender where the fluid is hottest, coolest, or what? Since I was looking for relative changes in temperature that might indicate a problem, it didn't really matter where the sender was placed. Put it somewhere convenient, get to know what the gauge reads under normal circumstances, and then watch for "abnormal" readings.

For the engine oil sender, the location was easy: I removed the drain plug in the oil pan and replaced it with VDO sender 323-055 that had the same threads (M14x1.5). With a cold engine, I didn't drain the oil, just quickly swapped sender for plug and caught the spill in a waste pan.

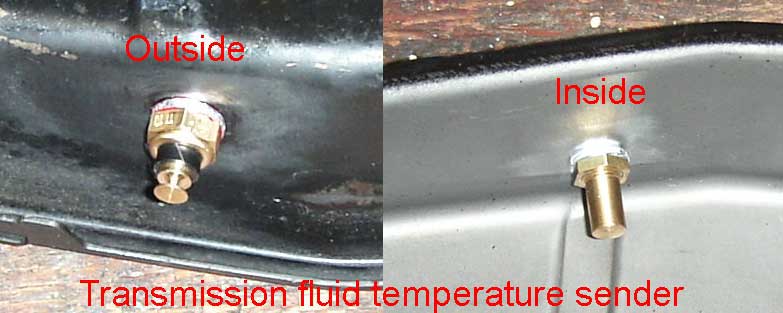

The transmission fluid sender was a little more work. The drain plug (M10x1) in the transmission pan points down and there isn't a lot of room between the plug and the belly panel ("sound encapsulation panel," as Mercedes calls it). I decided to remove the pan and drill a hole in the side for the sender. Since I could use any one of the many available senders, I chose VDO number 323-057 with 1/8-27 threads because it was inexpensive.

After draining the transmission fluid from the pan (about 2-1/2 quarts), I removed the pan and looked for a place where the sender could go without hitting anything. A place on the left (driver's) side near the back turned out to be best. The sender protrudes into the pan 1/2 inch and easily clears the filter, which lives back there.

A 3/8 inch hole, slightly enlarged with a reamer, provided the correct size hole. To be on the safe side, I used a nut and a crush washer on both sides of the pan and also used a little Loctite® 518 sealant to make sure I had a good seal. Note that 1/8-27 is a taper pipe thread, not a straight thread. I don't remember where I got the nuts but I think they were originally electric lamp hardware. This Rube Goldberg method is rather unprofessional but since there's no pressure in the transmission pan I suspected I could get away with it.

On the advice of Sixto (Hi there

) I ran the wires from the senders up through the floor of the car, using the same grommet as the neutral safety switch (NSS) and reverse light wiring. From there, the wires went into the console to the gauge panel. The switch is a miniature SPDT toggle, very non-Mercedes in appearance but also very small and, with its black handle, hard to see. I'll just have to hope that the concours judges miss it.

) I ran the wires from the senders up through the floor of the car, using the same grommet as the neutral safety switch (NSS) and reverse light wiring. From there, the wires went into the console to the gauge panel. The switch is a miniature SPDT toggle, very non-Mercedes in appearance but also very small and, with its black handle, hard to see. I'll just have to hope that the concours judges miss it.

All wiring to the gauge panel is done with connectors so that I can take the panel out of the car and work on it at my bench. The oil temperature gauge occupied the middle hole vacated by the voltmeter. Because three gauges is a tight fit in the ashtray space, I secured the gauges with hot melt glue — there isn't enough room for the usual mechanical hardware. The gauge panel is homemade, a sandwich of zebrano veneer over birch plywood over aluminum. The panel is trapped between the radio and the shift console so it doesn't need to be additionally secured. This also makes it easy to install and remove.

Having finished the installation, I refilled the transmission. The fluid, filter, and pan gasket were changed only a year ago so I reused everything. I left the belly panels off so I could check for leaks and, after removing the chocks, started the engine and took the car down off of the ramps.

Today I took the car for a drive to see how the new gauge worked. As I mentioned in the first paragraph, it seemed to take forever for the engine oil and transmission fluid to warm up enough to show on the gauge. The coolant had long since reached its usual 80ºC reading when the oil temperature needle finally budged off of its stop. Part of this was probably because the car had been sitting overnight in the cool of the garage (65ºF) before I backed it out into a blazing 95ºF California afternoon.

After running a couple of errands, I put the car on the freeway and ran it up to the next town (round trip about 50 miles). It took a good 10 miles to get the engine oil (Chevron Delo-400, 15W-40) up to 200ºF (93ºC) and even longer for the transmission fluid (NAPA house brand, I think) to get up to about 180ºF or 82ºC. Once these temperatures were reached, they stayed put, even when I returned to city traffic and slower speeds. Perhaps this is due to the large thermal mass of the engine and transmission. The outside air temperature most of the way was 100ºF so I ran the air conditioning continuously. The interior of the car stayed cool and the engine coolant temperature never went above 90ºC. Boost was 6 psi at 70 mph with the EGT at about 650ºF as usual.

Returning home, I parked the car and let it cool off before putting it back up on the ramps. Finding no leaks, I put the belly panels back on. Tomorrow I'll repeat this test to see if the panels make a difference and I'll update this thread at that time.

Jeremy

Discuss this DIY here.

-Jeremy5848

CategoryDiy