Sunroof Deflector Spring Replacement

on the 1985 300D (W123 Chassis)

by FranknBenz

10/09/07

CONDITION: Over time, torsion resistance wanes in the two springs that cause the air deflector to pop up when the roof is retracted.

REMEDY: Repair is effected by removal and replacement with new springs, and, due to changes in spring design, with spring slide supports.

PARTS REQUIRED: one (1) 124-782-06-35, Spring, Right; one (1) 124-782-05-35, Spring, Left; two (2) 124-782-00-46, Support, Slide.

TOOLS REQUIRED: #1 Phillips (+) screwdriver; #1 Flat (-) screwdriver; shop towels; shop light.

OTHER: ThreadLock, white lube; six (6) feet of nylon lawn trimmer.

Photo 1. The Patient. View looking across from driver's side. Sunroof retracted, air deflector lies flat. Springs no longer effective.

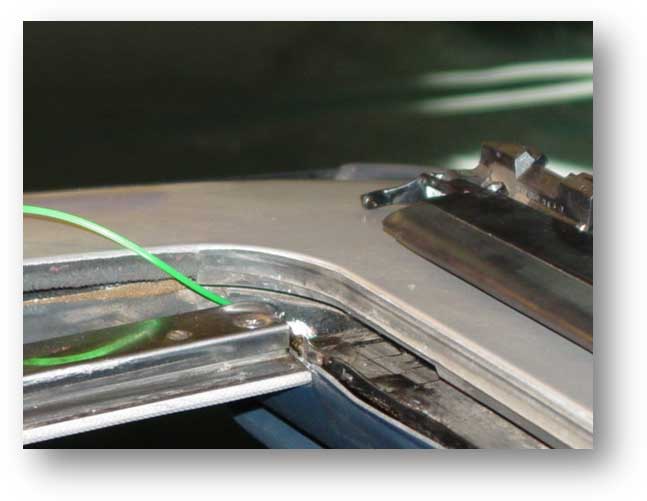

Photo 2. View looking forward along left edge of sunroof aperture. Cardboard added for photo clarity only. Begin by removing the two (2) side depressor rails, L and R. These push the air deflector down (when the springs are functioning) to position it in the cavity between the headliner and the sunroof metal pan.

Note that the rear end of each depressor rail is fitted with a tiny plastic bushing with two (2) apertures. These fit over the two metal tines in the roof gutter. GENTLY pull UP on the rear, freeing the bushing from the tines, then GENTLY pull to the rear, freeing the forward end of the depressor from the deflector actuator lugs.

Photo 3. View from driver's seat. Remove the six (6) trim screws; remove chrome strip. Set all aside carefully.

Photo 4. View from left side of vehicle. Note position of adjustment screw; count number of threads exposed. Remove screw completely and set aside carefully.

Photo 5. View looking forward, left side air deflector hinge assembly. (Blue tape retracts vinyl for the photo.) Note the highlighted rectangular plastic tab resting in its corresponding rectangular receiver in the metal roof gutter. Note the deceased spring.

TIP: + Replace one sprng at a time. In this way you can use the opposite side as a "mirror" image of what needs be done during reassembly.

With the flat blade, gently prise the hinge assembly forward, away from the metal. Gently lift up, rotating forward, say only 1/4 inch. Now do the other side. Note in the center there is a simple plastic hinge support. Note the V notch and alignment. Gently prise up and free it. Remove entire air deflector.

Photo 6. Detail of left hinge assembly, as removed from vehicle. New replacement parts consist of a spring of new design and a plastic piece called a "slide support". Note the differences in the short arm end of each spring. The old is bent into the spring coil; the new is bent outward. The black plastic slide support will fit over this short arm (dashed oval), capturing it; the "C" clip in the slide support will be snapped over the hinge edge of the deflector (solid thick line). See next photos for the rest of the assembly instructions..

Photo 7. Detail of new left spring fitted to the slide support. Note that springs are RIGHT and LEFT and are not interchangeable. Here the screwdriver serves in place of the hinge spring support shaft on the air deflector. The assembly will be pushed on the same way.

Photo 8. Detail of the reassembled LEFT hinge. The dashed yellow oval highlights the slide support.

+ If you noted the original relationship of parts, it will be easy to reassemble:

+ Clean up all parts prior to reassembly.

+ Assemble slide support to new spring, short end.

+ Clip slide support to the air deflector.

+ Start spring, long arm end first, over the projecting hinge spring support shaft, and push on, say, about 1/2 inch.

+ Carefully set the long arm of spring into receiver (dashed oval).

+ White spray lube all hinge surfaces.+ Assemble slide support to new spring, short end.

+ Clip slide support to the air deflector.

+ Start spring, long arm end first, over the projecting hinge spring support shaft, and push on, say, about 1/2 inch.

+ Carefully set the long arm of spring into receiver (dashed oval).

+ Shoot the spring itself with some canned air (or shop air) to get rid of any foreign materials.

Photo 9. View of the left front corner of the sunroof well.

With the air deflector fully re-assembled, take a break and do some preventive maintenance:

+ Check the forward sunroof cavity rubber seal; replace as necessary.

+ With a nylon trimmer line, clean out the left and right forward drain tubes. You should be able to see easily the small holes in each forward corner. About six feet later, the trimmer line should come out just forward of the door hinge.

+ Good time to inspect, clean, touch-up the forward deflector cavity area.

Photo 10. "After" view from driver's side, job complete.

Now to get the deflector assembly back in there...

+ No need to power smack anything. Do everything carefully, slowly, and gently and nothing will get broken.

+ Position the assembly over the forward edge of the sunroof cavity; begin on one end.

+ Key is first to align the rectangular hole in the metal gutter with the rectangular plastic stud in the hinge assembly.

+ Note with pride the new spring provides axial resistance between the hinge and deflector.

+ On an about 30 degree down angle, start the hinge forward, under the forward edge of the cavity, checking the alignment of the rectangles.

+ Continue to press in about 1/2 an inch, rotating down slightly. Do not push it in all the way at this time.

+ Move on to the center; align and start the middle hinge, noting the "V" notches in the hinge piece and the metal gutter rail.

+ Move on to the opposite hinge; align rectangles; start and finish with a "click"

+ Work backwards affixing the center hinge, then finish the opposite hinge, again, rectangle to rectangle.

+ Replace the chome trim; start but do not home the six screws. Check and tighten, center to sides. This is easily done from either front seat.

+ Restart the adjusting screws about one turn. Apply one drop of ThreadLock. Wait. Screw in at least to the original level.

+ Lube, then reinsert the L and R depression rails, mating to forward hinge studs first, then dropping down into the rear pivot points.

+ Test sunroof closing sequence by gently bumping the switch, checking alignment and set screw depression level. Adjust as necessary.

Take it out for a spin.

Total time for job is about twenty minutes...less time than perhaps it took to read all this!

Good luck with yours!

Discuss this DIY here.

-FranknBenz

CategoryDiy